Amomatic SM

Asphalt Plants

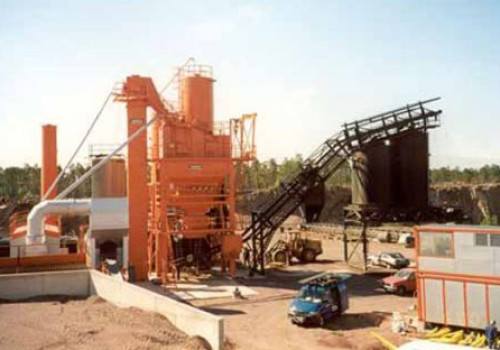

Semi-Mobile Asphalt Plants

Amomatic’s semi-mobile asphalt plants offer a high output of 160 to 300 t/h combined with easy relocation. The modular structure of the plant means that dismantling and installation can be done within days.

The modules used in Amomatic SM plants are designed to use as little extra parts as possible. For example, the bolt joints have been minimised, thus making the installation process easier. The plant travels safely from place to place with a trailer, thus lessening the logistic challenges. This makes it possible to move the production facilities multiple times during the paving season.

Mobility with high productivity

The SM asphalt plants can handle the same batches as the stationary models with the added function of mobility. In other words, you don't have to compromise on any fronts. Combined with Amomatic's production control and monitoring systems and recycling solutions, the SM plant gives your business a true competitive edge.

Plant Output Options

Basic Configuration

Amomatic 160 SM Technical Specifications

| standard model | options | |

| Plant output | 160 t/h | |

| Cold feeder | ||

| Number of hoppers | 4 | any number |

| Volume of one hopper | 9m3 | 12m3 or 15m3 |

| Drying drum | ||

| Diameter | 2250 mm | |

| Length | 8500 mm | |

| Burner output | 12,4 MW | |

| Burner fuels | light oil | bio gas, natural gas, heavy oil or combination burner |

| Drum drive | 4 x 15 kW | |

| Drum rotation speed | Adjustable by inverter | |

| Dry dust filter | ||

| Filter area | 620 m2 | 730 m2 |

| Exhaust fan control | Speed adjustment by inverter | |

| Mixer tower | ||

| Number of fractions | 5 | 4 or 6 |

| Hot bin volume | 25 m3 | 32 m3 or 50 m3 |

| Mixer batch size | 3000 kg | |

| Filter equipment | ||

| Filler silos | 30 m3 + 60 m3 | e.g. 2 x 60 m3 or 4 x 60 m3 |

| Asphalt mix storage | ||

| Capacity | 30 m3 | 30-300 m3 |

| Number of silos | 1 | 1-5 |

| Shape of silos | round | round or rectangular |

| Granulate feeder (option) | ||

| Silo capacity | 3 m3 or 6 m3 | |

| Amin feeder (option) | ||

| Size of tank | 1,5 m3 | |

| Bitumen tanks (option) | ||

| Size of tanks | 50 m3, horizontal | 50-100 m3, horizontal or vertical |

| Heating of tanks | electric heating | |

| Fuel tanks (option) | ||

| Size of tanks | 20 m3, horizontal | 20-100 m3, horizontal or vertical |

| Recycling equipment (option) | ||

|

Cold recycling (recycling ring) or |

||

Amomatic 200 SM Technical Specifications

| standard model | options | |

| Plant output | 200 t/h | |

| Cold feeder | ||

| Number of hoppers | 4 | any number |

| Volume of one hopper | 9m3 | 12m3 or 15m3 |

| Drying drum | ||

| Diameter | 2350 mm | |

| Length | 9000 mm | |

| Burner output | 15,5 MW | |

| Burner fuels | light oil | bio gas, natural gas, heavy oil or combination burner |

| Drum drive | 4 x 15 kW | |

| Drum rotation speed | Adjustable by inverter | |

| Dry dust filter | ||

| Filter area | 730 m2 | 840 m2 |

| Exhaust fan control | Speed adjustment by inverter | |

| Mixer tower | ||

| Number of fractions | 5 | 4 or 6 |

| Hot bin volume | 25 m3 | 32 m3 or 50 m3 |

| Mixer batch size | 3000 kg | |

| Filter equipment | ||

| Filler silos | 30 m3 + 60 m3 | e.g. 2 x 60 m3 or 4 x 60 m3 |

| Asphalt mix storage | ||

| Capacity | 100 m3 | 30-300 m3 |

| Number of silos | 2 | 1-5 |

| Shape of silos | rectangular | round or rectangular |

| Granulate feeder (option) | ||

| Silo capacity | 3 m3 or 6 m3 | |

| Amin feeder (option) | ||

| Size of tank | 1,5 m3 | |

| Bitumen tanks (option) | ||

| Size of tanks | 50 m3, horizontal | 50-100 m3, horizontal or vertical |

| Heating of tanks | electric heating | |

| Fuel tanks (option) | ||

| Size of tanks | 20 m3, horizontal | 20-100 m3, horizontal or vertical |

| Recycling equipment (option) | ||

|

Cold recycling (recycling ring) or |

||

Amomatic 240 SM Technical Specifications

| standard model | options | |

| Plant output | 240 t/h | |

| Cold feeder | ||

| Number of hoppers | 4 | any number |

| Volume of one hopper | 12m3 | 9m3 or 15m3 |

| Drying drum | ||

| Diameter | 2500 mm | |

| Length | 9000 mm | |

| Burner output | 18,4 MW | |

| Burner fuels | light oil | bio gas, natural gas, heavy oil or combination burner |

| Drum drive | 4 x 18,5 kW | |

| Drum rotation speed | Adjustable by inverter | |

| Dry dust filter | ||

| Filter area | 840 m2 | 960 m2 |

| Exhaust fan control | Speed adjustment by inverter | |

| Mixer tower | ||

| Number of fractions | 5 | 4 or 6 |

| Hot bin volume | 25 m3 | 32 m3 or 50 m3 |

| Mixer batch size | 4000 kg | |

| Filter equipment | ||

| Filler silos | 60 m3 + 60 m3 | e.g. 4 x 60 m3 |

| Asphalt mix storage | ||

| Capacity | 100 m3 | 30-300 m3 |

| Number of silos | 2 | 1-5 |

| Shape of silos | rectangular | round or rectangular |

| Granulate feeder (option) | ||

| Silo capacity | 3 m3 or 6 m3 | |

| Amin feeder (option) | ||

| Size of tank | 1,5 m3 | |

| Bitumen tanks (option) | ||

| Size of tanks | 50 m3, horizontal | 50-100 m3, horizontal or vertical |

| Heating of tanks | electric heating | |

| Fuel tanks (option) | ||

| Size of tanks | 20 m3, horizontal | 20-100 m3, horizontal or vertical |

| Recycling equipment (option) | ||

|

Cold recycling (recycling ring) or |

||

Amomatic 300 SM Technical Specifications

| standard model | options | |

| Plant output | 300 t/h | |

| Cold feeder | ||

| Number of hoppers | 4 | any number |

| Volume of one hopper | 15m3 | 9m3 or 12m3 |

| Drying drum | ||

| Diameter | 2800 mm | |

| Length | 10000 mm | |

| Burner output |

22,5 MW |

|

| Burner fuels | light oil | bio gas, natural gas, heavy oil or combination burner |

| Drum drive | 4 x 22 kW | |

| Drum rotation speed | Adjustable by inverter | |

| Dry dust filter | ||

| Filter area | 1200 m2 | 1460 m2 |

| Exhaust fan control | Speed adjustment by inverter | |

| Mixer tower | ||

| Number of fractions | 5 | 4 or 6 |

| Hot bin volume | 32 m3 | 50 m3 |

| Mixer batch size | 4000 kg | |

| Filter equipment | ||

| Filler silos | 70 m3 + 70 m3 | e.g. 4 x 70 m3 |

| Asphalt mix storage | ||

| Capacity | 100 m3 | 30-300 m3 |

| Number of silos | 2 | 1-5 |

| Shape of silos | rectangular | round or rectangular |

| Granulate feeder (option) | ||

| Silo capacity | 3 m3 or 6 m3 | |

| Amin feeder (option) | ||

| Size of tank | 1,5 m3 | |

| Bitumen tanks (option) | ||

| Size of tanks | 50 m3, horizontal | 50-100 m3, horizontal or vertical |

| Heating of tanks | electric heating | |

| Fuel tanks (option) | ||

| Size of tanks | 20 m3, horizontal | 20-100 m3, horizontal or vertical |

| Recycling equipment (option) | ||

|

Cold recycling (recycling ring) or |

||